Good quality Cuplock Scaffold - Fabricated Steel Frame Scaffolding with SGS Certificate – Sampmax

Good quality Cuplock Scaffold - Fabricated Steel Frame Scaffolding with SGS Certificate – Sampmax Detail:

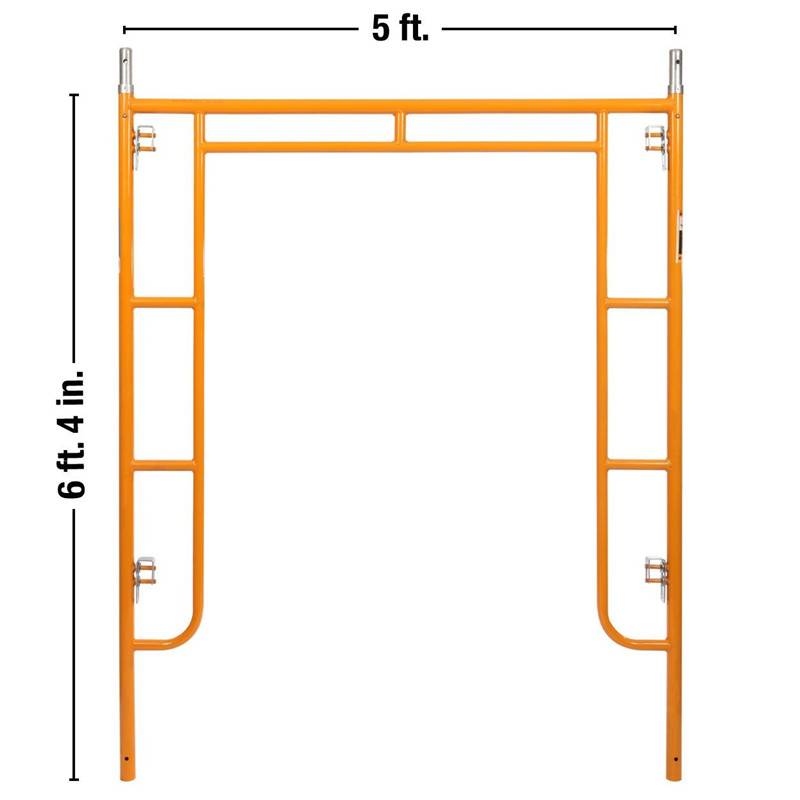

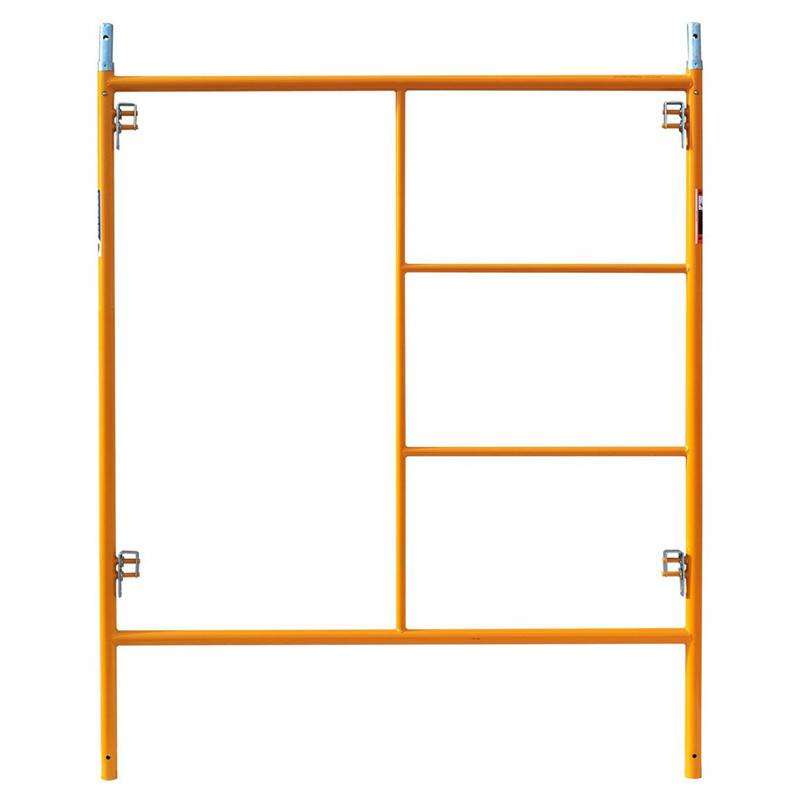

Frame scaffolding is mainly composed of vertical frame, horizontal frame, cross diagonal brace, scaffold board, adjustable base, etc. Because the vertical frame is in the shape of “door”, it is called door-type scaffolding.

Fabricated Steel Frame Scaffolding with SGS Certificate

Frame scaffolding is one of the most widely used scaffolds in construction. In the early 1950s, the United States first developed portal scaffolding. Because of its simple assembly and disassembly, convenient movement, good bearing performance, safe and reliable use, good economic benefits and other advantages, the development speed is very fast.

The frame scaffolding is one of the earliest used, most widely used, and most versatile scaffolds among all types of scaffolding.

Specifications

Frame scaffolding is mainly composed of vertical frame, horizontal frame, cross diagonal brace, scaffold board, adjustable base, etc. Because the vertical frame is in the shape of “door”, it is called door-type scaffolding. It can not only be used as internal and external scaffolding for construction, but also as formwork support, table mold support and mobile scaffolding. It has multiple functions, so it is also called multifunctional scaffolding. Its main features are simple assembly and disassembly, high construction efficiency, and the assembly and disassembly time is about 1/3 of the fastener scaffolding, the load-bearing performance is good, the use is safe and reliable, and the use strength is 3 times that of the fastener scaffolding, long service life and good economic benefits. Fastener scaffolding can generally be used for 8 to 10 years, and door scaffolding can be used for 10 to 15 years.

The width: 914mm, 1219mm, 1524mm

Height: 1524mm, 1700mm, 1930mm

Weight: 10.5KG, 12.5KG, 13.6KG

Surface treatment: Painted, Electro-galvanized, Hot Dip Galvanized, Pre-galvanized

The width: 914mm, 1219mm, 1524mm

Height: 914mm, 1524mm, 1700mm, 1930mm

Weight: 6.7KG, 11.2KG, 12.3KG, 14.6KG

Surface treatment: Painted, Electro-galvanized, Hot Dip Galvanized, Pre-galvanized

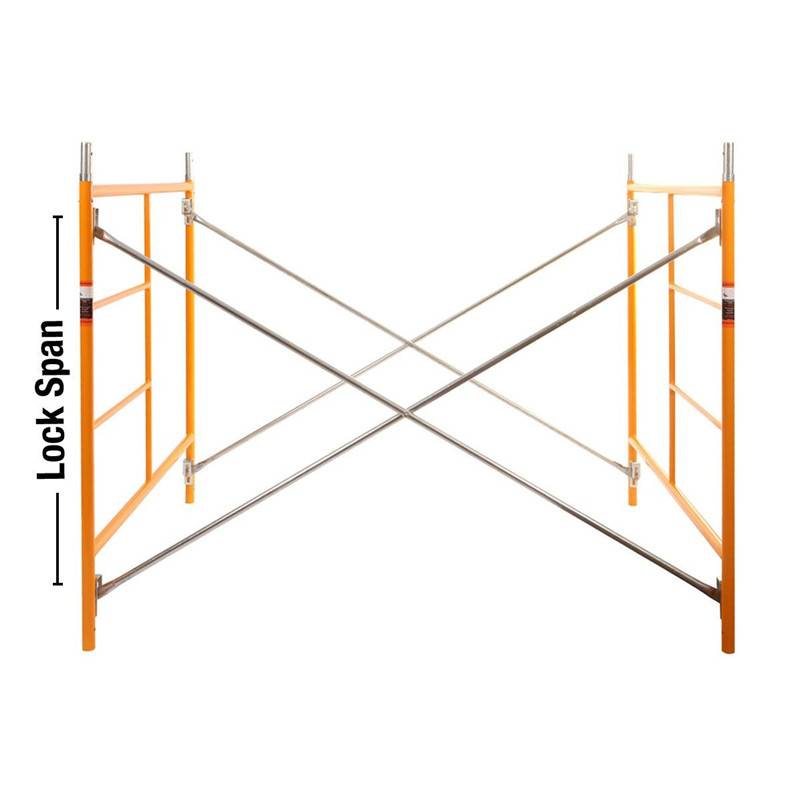

Cross Brace

| Specification | Weight | Surface Treatment |

| 21×1.4x1363mm | 1.9kg | Painted, Electro-galvanized, Hot Dip Galvanized, Pre-galvanized |

| 21×1.4x1724mm | 2.35kg | |

| 21×1.4x1928mm | 2.67kg | |

| 21×1.4x2198mm | 3.0kg |

Precautions for building construction

Iintermediate Transom is a middle bracket used as a cuplock scaffold walkplank to provide safety support. The inward locking is set at one end to prevent horizontal movement during use.

| Raw Material | Q235 |

| Sizes | 565mm/795mm/1300mm/1800mm |

| Diameter | 48.3*3.2mm |

| Surface Treatment | Painted/Electro-Galvanized/Hot dip galvanized |

| Weight | 2.85-16.50kg |

Cuplock Scaffolding Diagonal Brace

Portal scaffolding can be used not only as internal and external scaffolding, but also as formwork support, so the following requirements are considered in the construction use:

The scaffolding should have enough area to meet the requirements of workers’ construction operations and meet the needs of material transportation and stacking;

With sufficient strength and overall rigidity, the door frame is firm and stable, safe and reliable;

It can be combined and assembled into mold bases of various heights up to 300mm;

Flexible assembly and disassembly, convenient transportation, strong versatility, and can be used in multiple cycles;

Scaffolding has fewer specifications and accessories, which can meet the needs of multiple purposes.

Certificates & Standard

Quality Management System: ISO9001-2000.

Tubes Standard: ASTM AA513-07.

Couplings Standard: BS1139 and EN74.2 standard.

Product detail pictures:

Related Product Guide:

With this motto in mind, we have become one of the most technologically innovative, cost-efficient, and price-competitive manufacturers for Good quality Cuplock Scaffold - Fabricated Steel Frame Scaffolding with SGS Certificate – Sampmax , The product will supply to all over the world, such as: Chicago, Myanmar, Colombia, In order to carry out our goal of "customer first and mutual benefit" in the cooperation, we establish a specialist engineering team and a sales team to supply the best service to satisfy our customers' requirements. Welcome you to cooperate with us and join us. We have been your best choice.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.